Beskrivning

AECO – THE SMART SOLUTION

High- purity copper (Tellurium Copper)

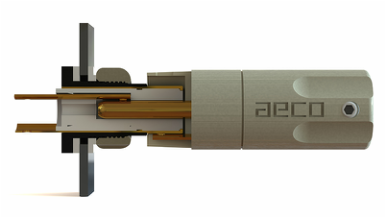

Concept

The STARS can be assort and unilateral replace with other standard RCA plug and jack.

By reducing the size of the conductor and path, to reduce Resistance, Capacitance and Inductance reaction when signal transmit .

Non-coaxial conduction are able to use single point conduction while plug connect to jack.

The Plug is made with Nylon composite material which provide sufficient flexibility and clamping force to connect tightly with Jack.

The Jack is made with insulation material which isolated from the metal plate and reducing the impact from external factors.

The conductor is made from high- purity copper (Tellurium Copper) with gold plating (10u”).

By using highest quality of design techniques and material to provide customer who has “High End” requirement.

By reducing the size of the conductor and path, to reduce Resistance, Capacitance and Inductance reaction when signal transmit .

Non-coaxial conduction are able to use single point conduction while plug connect to jack.

The Plug is made with Nylon composite material which provide sufficient flexibility and clamping force to connect tightly with Jack.

The Jack is made with insulation material which isolated from the metal plate and reducing the impact from external factors.

The conductor is made from high- purity copper (Tellurium Copper) with gold plating (10u”).

By using highest quality of design techniques and material to provide customer who has “High End” requirement.

Levereras i en snygg förpackning.

Levereras i en snygg förpackning.Det medflöjer extra skruvar (torx T6).

Delivered in a nice package.

Extra screws (torx T6) are included.

Extra screws (torx T6) are included.

Description

Mechanical structure:

The contact pin is formed on the body by plastic injection.

The STAR modeling use the characteristics of Nylon composite material.

which provide enough flexibly to connect with jack tightly.Grounding use Latch to be assembled tightly with body.

The Non-coaxial design makes the signal reaches

by “Single Point Contact” while plug connect to jack.After well soldering the wires on positive and negative part,

the shell locked with body by screwing and to fix the cable with shell stable by a screw.Screws with the finished products.

(4/6mm 4 screws per each.)

The contact pin is formed on the body by plastic injection.

The STAR modeling use the characteristics of Nylon composite material.

which provide enough flexibly to connect with jack tightly.Grounding use Latch to be assembled tightly with body.

The Non-coaxial design makes the signal reaches

by “Single Point Contact” while plug connect to jack.After well soldering the wires on positive and negative part,

the shell locked with body by screwing and to fix the cable with shell stable by a screw.Screws with the finished products.

(4/6mm 4 screws per each.)

Material:

ARP-4045

Contact Pin:Tellurium Copper(#C14500 / copper contains over 99%)

Grounding:Copper (#C1100 / copper contains over 99.5%)

Body: Glass fiber reinforced nylon (Red / White)

Shell: Brass alloy (#C3604)

Sleeve: POM

Screw: Iron

ARP-4045

Contact Pin:Tellurium Copper(#C14500 / copper contains over 99%)

Grounding:Copper (#C1100 / copper contains over 99.5%)

Body: Glass fiber reinforced nylon (Red / White)

Shell: Brass alloy (#C3604)

Sleeve: POM

Screw: Iron

Finish:

ARP-4045

Contact Pin: 10u” Gold plating (no nickel base)

Grounding: 10u” Gold plating (no nickel base)

ARP-4045

Contact Pin: 10u” Gold plating (no nickel base)

Grounding: 10u” Gold plating (no nickel base)

Electrical Characteristics:

Contact resistance < 0.3 mOhm (It was test by ARJ-4043.)

Contact resistance < 0.3 mOhm (It was test by ARJ-4043.)

Dimension:

Biggest OD 13.7mm

Cable hole

Sleeve is contained in finished product 8.5mm.

Sleeve is not contained in finished product 10.5mm.

Total Length 46.4mm

Biggest OD 13.7mm

Cable hole

Sleeve is contained in finished product 8.5mm.

Sleeve is not contained in finished product 10.5mm.

Total Length 46.4mm

Packing:

Vacuum Bag(4Pcs/1Set)

Vacuum Bag(4Pcs/1Set)

Recommend soldering temperature:

Temperature Soldering Iron, please keep 380 °C within 5~8 second.

Temperature Soldering Iron, please keep 360 °C within 9~13 second.

Temperature Soldering Iron, please keep 340 °C within 13~18 second.

Temperature Soldering Iron, please keep 320 °C within 19~25 second.

Temperature Soldering Iron, please keep 380 °C within 5~8 second.

Temperature Soldering Iron, please keep 360 °C within 9~13 second.

Temperature Soldering Iron, please keep 340 °C within 13~18 second.

Temperature Soldering Iron, please keep 320 °C within 19~25 second.

Product production process comply with RoHS.

Product made new TW patent No. D158416.

Product made new TW patent No. D158416.